Quick Air Modular Aluminium Piping

20 & 40 Bar Leak-Proof Air Lines

Introduction

Quick Air® modular aluminium piping—manufactured by Canares Automation Pvt. Ltd. and supplied by Ahuja Group (authorised dealer)—delivers a corrosion‑free, energy‑saving alternative to MS and GI pipe networks. The lightweight 6063‑T5 aluminium tube, combined with push‑fit or integrated fittings, installs up to 70 % faster than welded or threaded systems, keeps pressure drop ultra‑low, and stays contaminant‑free for life. Available in both 20 bar and 40 bar ratings (Ø 20 mm – 205 mm), Quick Air is ready for everything from CNC shops to large‑scale, high‑pressure PET bottling lines.

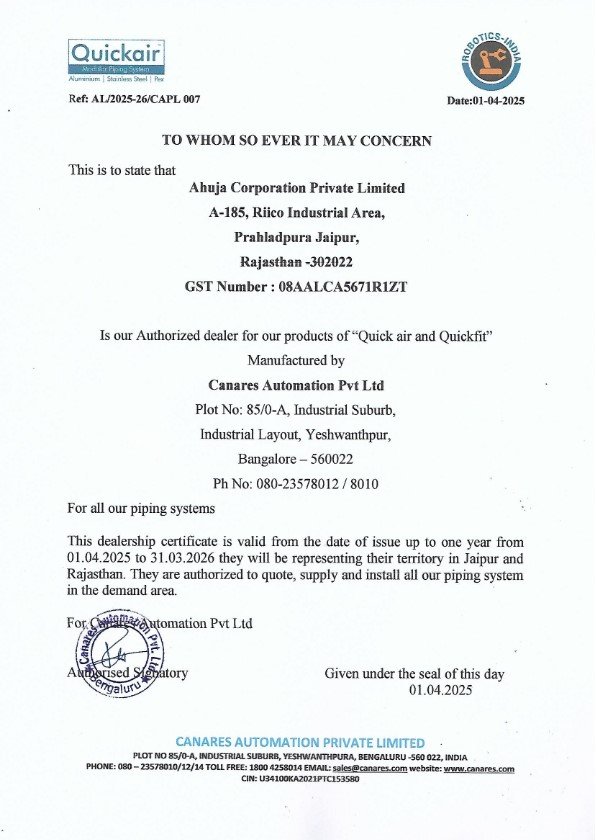

Dealership Certification

Quick Air – Premium Aluminum Piping Systems for Compressed Air

Ahuja Group is an authorized channel partner of Quick Air, a globally trusted brand for aluminum piping solutions. Quick Air systems are engineered for high efficiency, corrosion resistance, and quick installation — ideal for compressed air, vacuum, and inert gas applications. We deliver reliable, leak-proof, and modular piping systems that enhance plant productivity and reduce energy losses across industrial facilities

Product Portfolio

Quick Air Modular Aluminium Piping

Aluminium Pipes

6063‑T5 alloy, blue powder‑coat finish, Ø 20 mm – 205 mm in 3 m & 6 m lengths; PN 20 and PN 40 ratings.

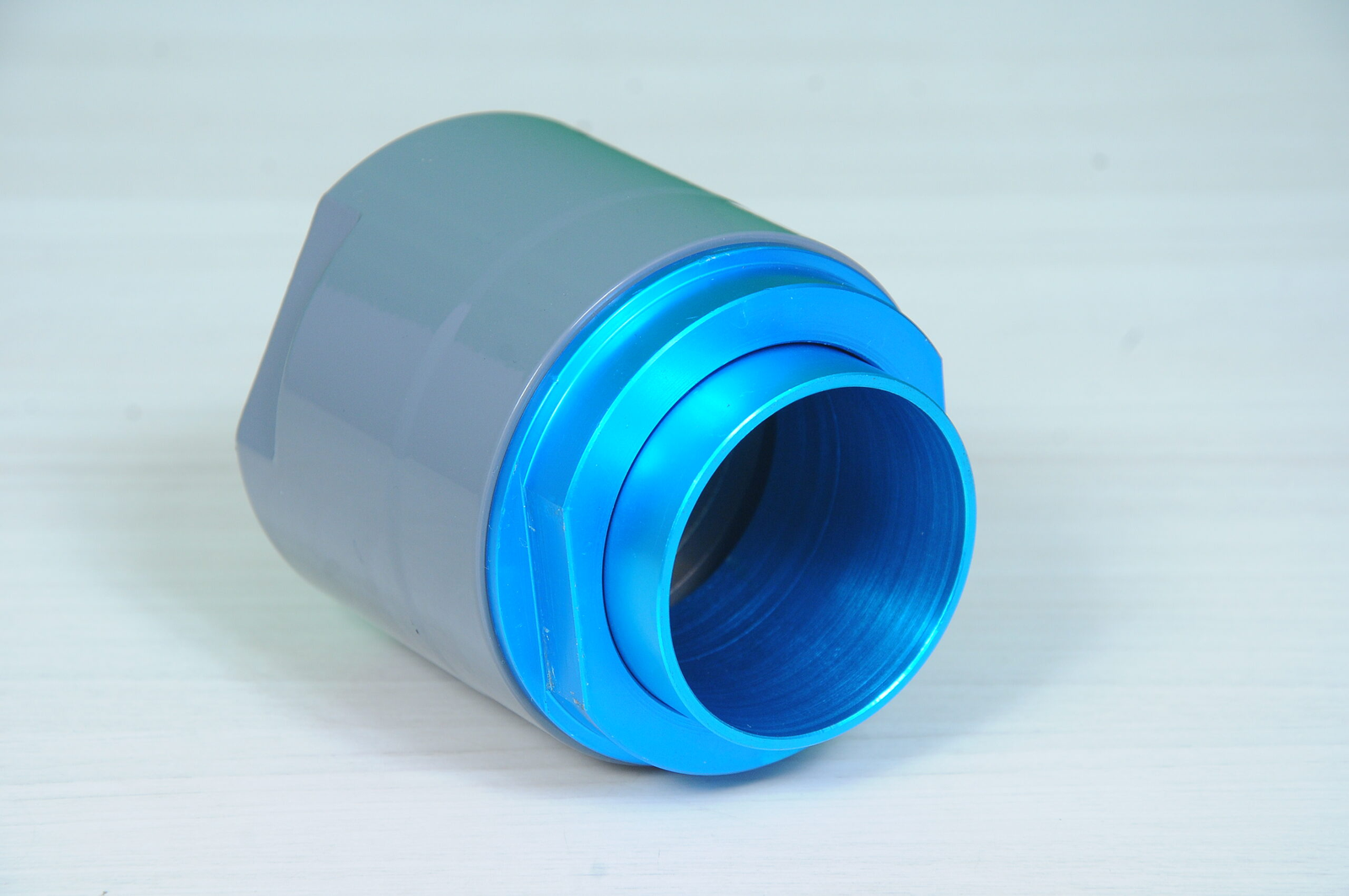

Push-Fit Fittings (Al Caps)

Aluminium body with aluminium caps & bushes, sizes 20 – 63 mm, 20 bar; quickest install for general shop air.

Push-Fit Fittings (Eco Caps)

Aluminium body with engineering‑plastic caps & bushes, sizes 20 – 63 mm, 20 bar; lighter and cost‑optimised.

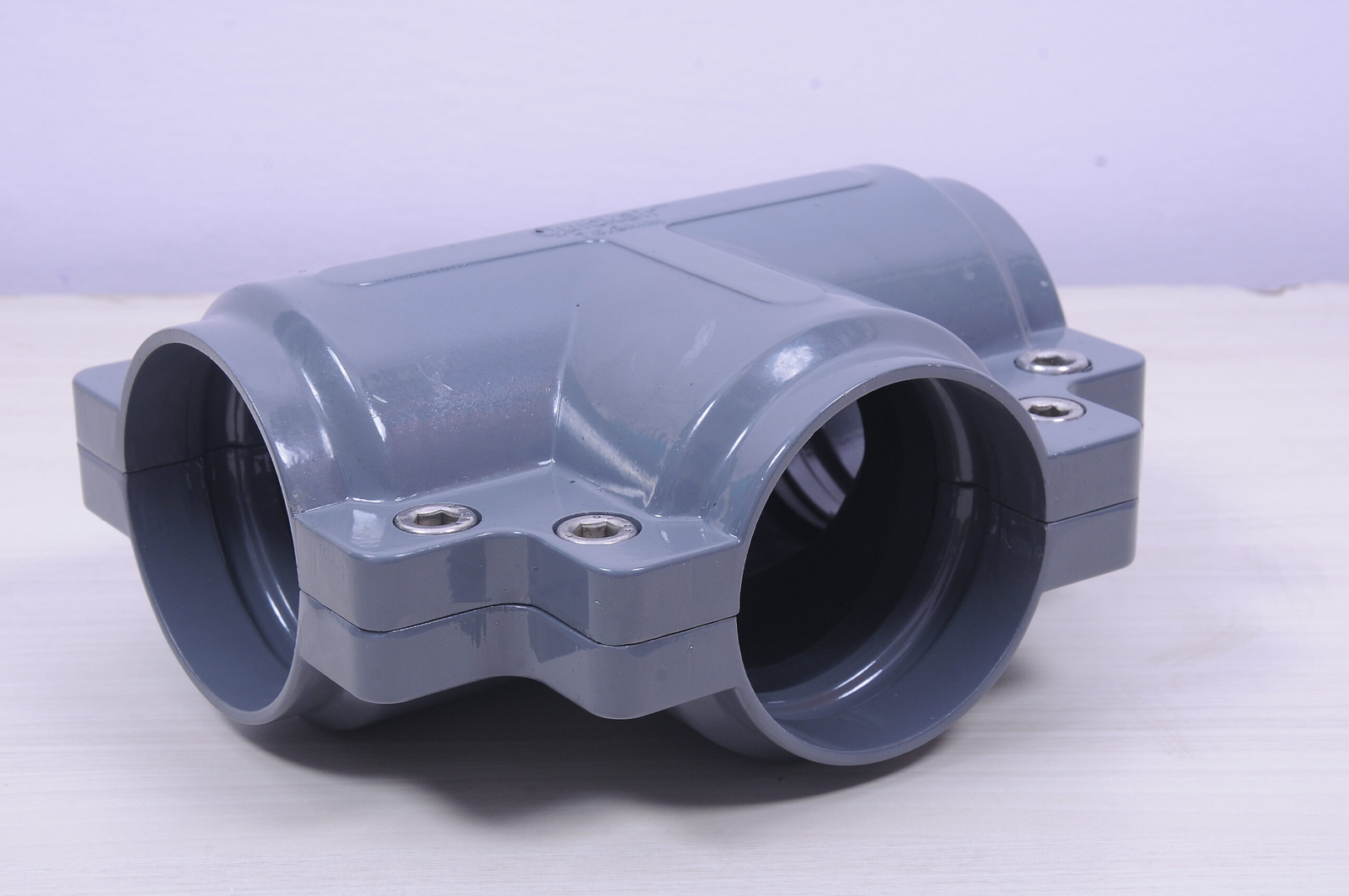

Integrated Heavy-Duty Fittings

One‑piece solid‑aluminium design, sizes 20 – 205 mm; handles 20 bar standard and 40 bar PET lines.

Valves & Isolation Hardware

Full‑bore ball valves, butterfly valves, pressure indicators, drain points—all colour‑matched to pipe OD.

Quick-Drop Outlets & Manifolds

Pre‑tapped blocks (½″–1″ BSP/NPT) with optional mini ball‑valve, drip‑leg and sight‑glass kits.

Mounting & Support

Colour‑coded pipe clips, wall brackets, ceiling hangers and safety cable stanchions up to DN 200.

Installation Tools & Spares

Calibrated pipe cutters, deburring reamers, torque spanners, dual‑seal O‑ring kits, service lubricants.

Products

Our Installation

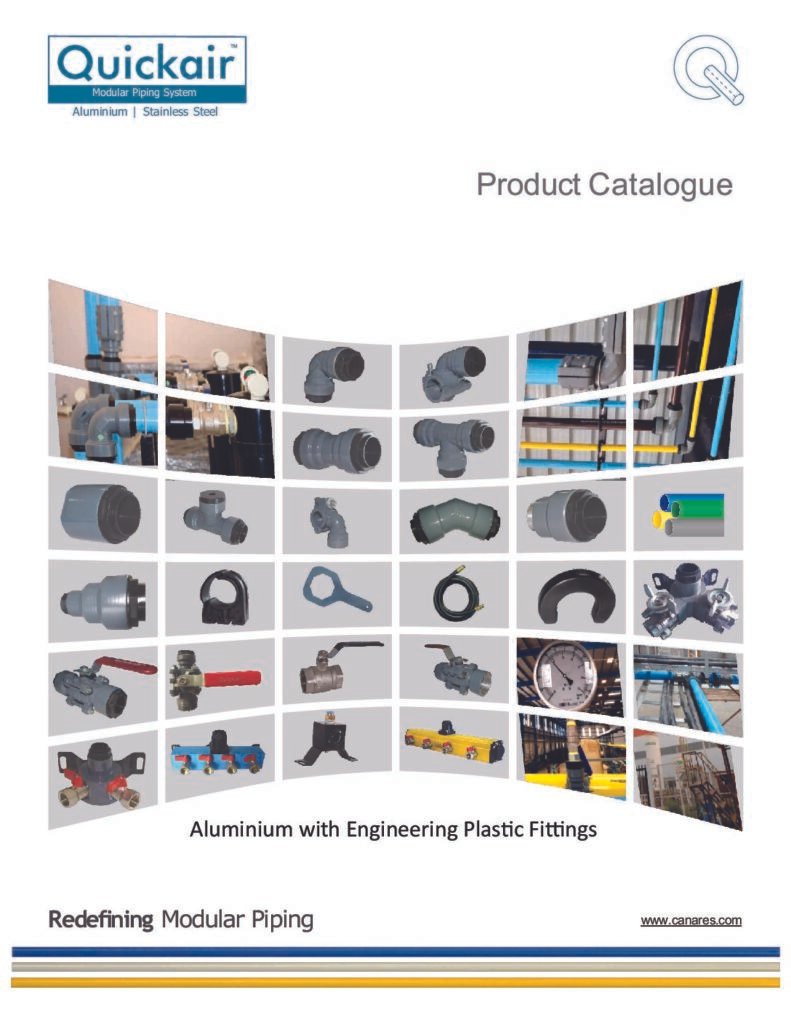

Catalogues

| Image | Title | Type | Size | Counter | Link |

|---|---|---|---|---|---|

|

|

pdf |

13 MB |

2 |

||

|

|

pdf |

14 MB |

3 |

||

|

|

pdf |

12 MB |

7 |

Product Features

Full‑bore, laminar flow design

minimal pressure drop & lower kW/CFM

Light weight No corrosion

aluminium alloy won’t rust or scale, maintaining ISO 8573 air quality.

Reusable

all fittings can be dismantled and re‑assembled during plant expansions.

Hot‑swap ready

connect to existing steel, copper or PPR lines via transition fittings.

Wide fluid compatibility

compressed air, vacuum (‑29.3” Hg), nitrogen, CO₂, argon.

Operating window

20 °C to +180 °C (option 200 °C), UL 94 HB non‑flammable materials

25-Year Life & 10-Year Warranty

third‑party tested to ASME B31.1 / PED 2014‑68‑EU.

Push-Fit / Integrated Joints

secure in seconds, fully re‑usable; no welding, threading or hot work

High Pressure Ready

standard series to 20 bar; heavy‑duty series to 40 bar for PET and blow‑moulding lines.

Technical Specifications

Parameter

Specification

Pipe Material

Seamless aluminium alloy 6063-T5, blue powder-coat (RAL 5012)

Outside-Diameter Range

20 mm – 205 mm (nominal)

Working Pressures

• PN 20 line: 0 – 20 bar (g) • PN 40 line: 0 – 40 bar (g)

Vacuum Rating

Up to −29.3 inHg (−990 mbar)

Operating Temperature

−20 °C to +180 °C continuous (short peaks to +200 °C)

Joint Sealing

Dual-lip HNBR O-rings; EPDM / Viton® options for high-temp or chemical duty

Internal Surface Roughness

≤ 0.8 µm Ra → full-bore, laminar flow

Compatibility

Compressed air, nitrogen, CO₂, argon, inert gases, vacuum

Standards & Compliance

ASME B31.1 / B31.3 • PED 2014/68/EU • ISO 8573 air-quality compatible

Colour Coding

Factory blue for compressed air; other colours (grey, black) on request

Warranty

10 years against manufacturing defects when installed by authorised technicians

Applications

FESTO’s industrial automation product range includes

General Engineering

Food & Pharma

Electronics & Semiconductor

Automotive & Tyre

PET & Beverage

Textile Mills

Foundry & Steel

Why Choose Quick Air?

• 26 + years of modular‑piping innovation

10‑year manufacturer warranty

Full range 20 mm

205 mm with matching valves, brackets, manifolds and FRLs.

ISO 9001:2015 production, PED 2014/68/EU compliance.

Proven at 1 000 + Indian plants—textile, pharma, solar, electronics, auto and PET lines.

Faster ROI

labour ≤ 20 % of install cost vs. 60 – 80 % for welded lines.

Why Buy from Ahuja Group?

Authorised Quick Air dealer with factory‑trained design & installation team

Local stock of tubes, elbows, tees & drop assemblies up to 63 mm—same‑day dispatch.

In‑house CAD layout & pressure‑drop calculations (zero‑cost).

On‑site erection crew & certified aluminium‑pipe installers.

24 × 7 breakdown support + backup rental compressor option during shutdowns.

Turnkey capability: integrates with Anest Iwata compressors & Festo pneumatics.

Frequently Asked Questions

Can Quick Air handle oil‑free air?

Yes—aluminium and EPDM seals resist oil‑free condensate and remain corrosion‑free.

How long does installation take?

Push‑fit sections install up to 70 % faster—expect ~1 day per 250 m of 32 mm pipe with a two‑man crew.

Can I mix 20 bar and 40 bar pipes?

Yes—use our step‑down integrated reducers to move from PET high‑pressure 40 bar mains to 20 bar shop air loops

What maintenance is required?

None other than periodic leak checks; all fittings are reusable if you relocate machines

Do you supply stainless‑steel or PEX variants?

We do—speak with our projects team for mixed‑media layouts

Ready to slash pressure‑drop and installation time?

Submit your line length & flow data—or call +91 7023301222—and get a free aluminium piping design & ROI report within 24 hours.

Get Invites to Explore the Quick Air Aluminium Air Line Range

Complete Your Automation Stack

Air Compressors & Vaccum Pumps

Anest Iwata

Reliable oil-free and lubricated air compressors and vaccum pumps designed for clean, efficient, and continuous industrial performance

Aluminium Composite Air Pipeline

UNIPRO

Composite air pipelines provide durable, corrosion-resistant, air distribution with easy installation, high flow efficiency, and long service life.

PPR Water Pipeline

KPT

Turnkey PPR pipeline solutions for chilled water and process water applications in industrial facilities

Material Handling Equipment

Stackeasy

Innovative lifting, shifting, and storage equipment to streamline factory and warehouse material flow

Pneumatic Automation

FESTO

Advanced pneumatic and electric automation solutions for industrial control and motion applications